Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

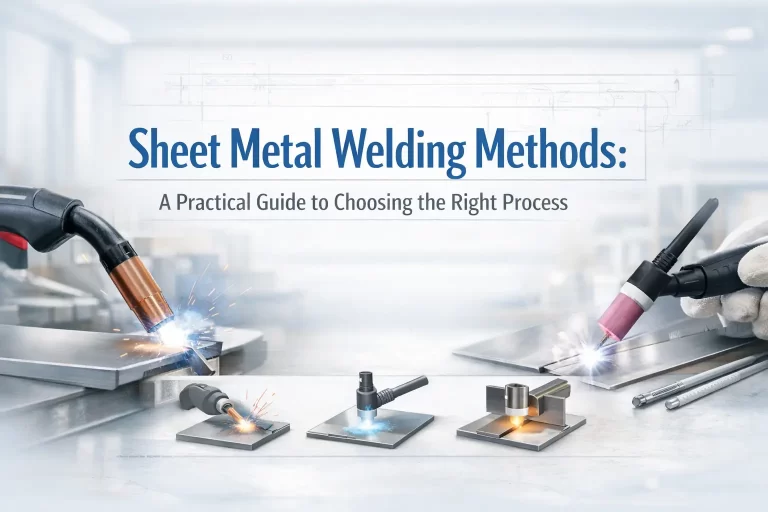

Sheet metal welding plays a vital role in modern manufacturing, enabling strong, reliable joints for everything from simple brackets to complex structural assemblies. With a wide range of welding methods available, choosing the right process is essential to achieving the…

Brass CNC machining is a critical process in modern manufacturing, allowing for the production of high-precision components used in electronics, automotive, and aerospace industries. With its excellent machinability, corrosion resistance, and electrical conductivity, brass is a popular material choice for…

Creating professional prototypes requires more than just good design—it also depends on the right manufacturing partner. From material selection and process optimization to tight tolerances and fast turnaround, working with an experienced prototyping supplier can make a significant difference in…

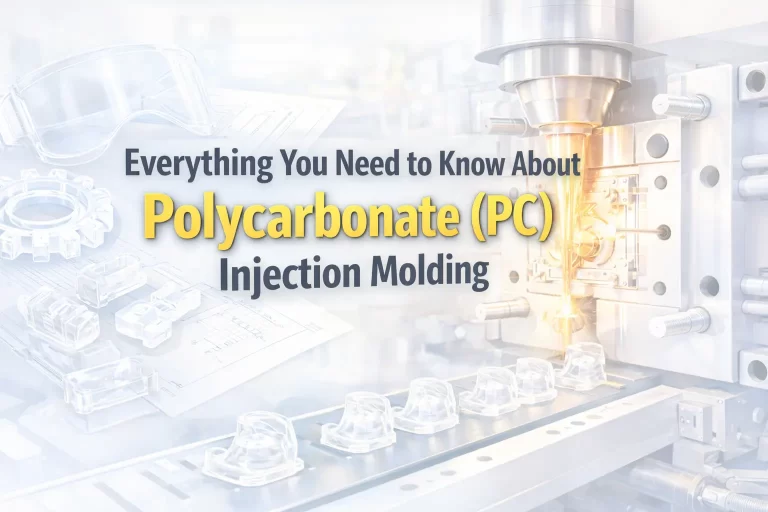

Polycarbonate (PC) injection molding is a widely used manufacturing process for producing high-performance plastic parts that require excellent strength, impact resistance, and optical clarity. Known for its durability and dimensional stability, polycarbonate is commonly applied in industries such as automotive,…

Because anodizing provides long-lasting protection, requires little maintenance, and improves surface durability, it has become a preferred finishing option across many industries. Any metal that can be anodized is often treated this way, simply because the benefits outweigh the cost.…

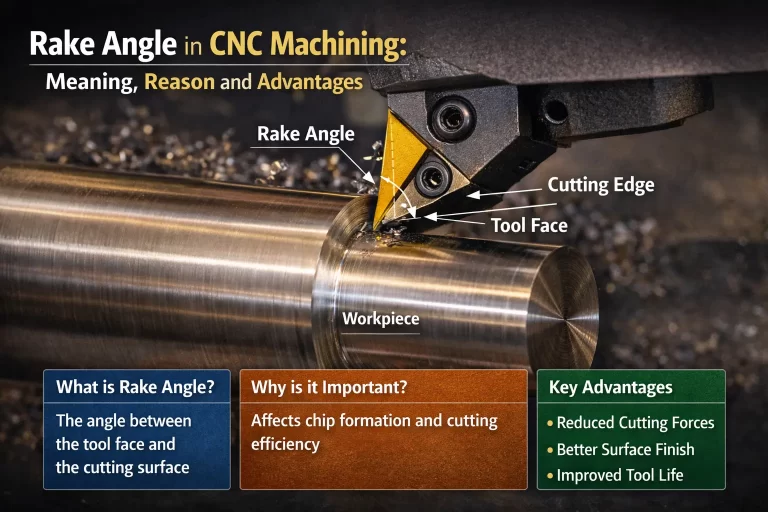

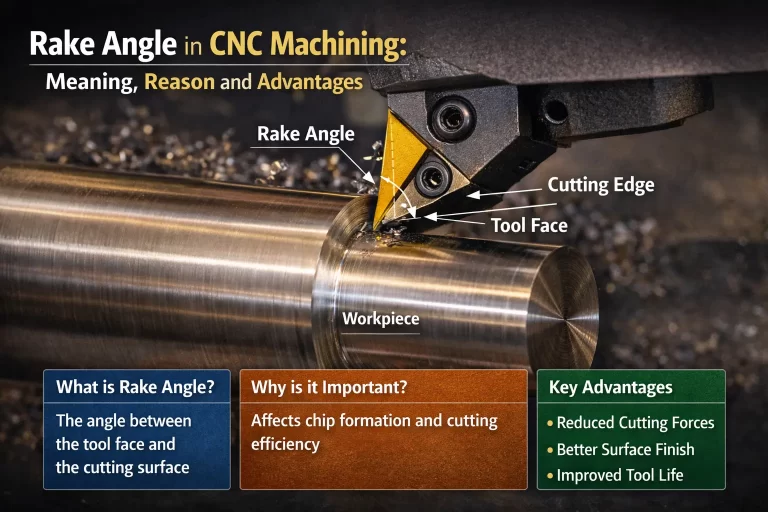

Choosing the right rake angle isn’t just about picking a number from a chart—it’s about understanding your material, machine, and machining goals. Here’s a practical approach to selecting the optimal rake angle for your specific project: In our previous article,…

If you have ever wondered why one tool cuts through metal like butter while another seems to struggle with every millimeter, the answer often lies in a small but powerful detail: the rake angle. It’s the part of the cutting…

Black oxide coating is a widely used metal finishing process that helps protect ferrous metals from corrosion while improving their overall performance. Ferrous metals are known for their exceptional strength and hardness. However, they are also equally well-known for their…

Which materials are suitable for prototyping medical devices? Choosing the right materials for prototyping medical devices The choice of materials for prototyping medical devices is crucial due to stringent safety, sterilization, and durability requirements. Materials must be biocompatible, meaning they…

What techniques are used in medical device prototyping? Medical device prototyping utilizes a wide variety of techniques, ranging from additive manufacturing to subtractive manufacturing, each selected according to the specific requirements of the project. These techniques include: 3D printing: Uses…