Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Because anodizing provides long-lasting protection, requires little maintenance, and improves surface durability, it has become a preferred finishing option across many industries. Any metal that can be anodized is often treated this way, simply because the benefits outweigh the cost. In most cases, anodizing also improves the appearance of the part, making it both practical and visually appealing. To better understand why it’s so widely used, let’s take a closer look at what anodizing is and how the process works.

Anodizing is an electrochemical surface treatment process mainly used for aluminum and its alloys. The process increases the thickness of the metal’s natural oxide layer, creating a hard, protective surface that becomes part of the material itself. Unlike paint or coating, anodizing does not sit on top of the metal, so it won’t peel, chip, or flake during use.

During anodizing, the metal part is immersed in an acid electrolyte bath and exposed to an electric current. This controlled reaction forms a uniform oxide layer that improves corrosion resistance, wear resistance, and surface hardness. At the same time, the porous structure of the anodized layer allows the surface to absorb dyes, making it possible to achieve a wide range of colors without affecting part dimensions.

Because of its reliability, clean appearance, and cost-effectiveness, anodizing is widely used in CNC machining, aerospace components, electronics housings, and industrial parts where both performance and appearance matter.

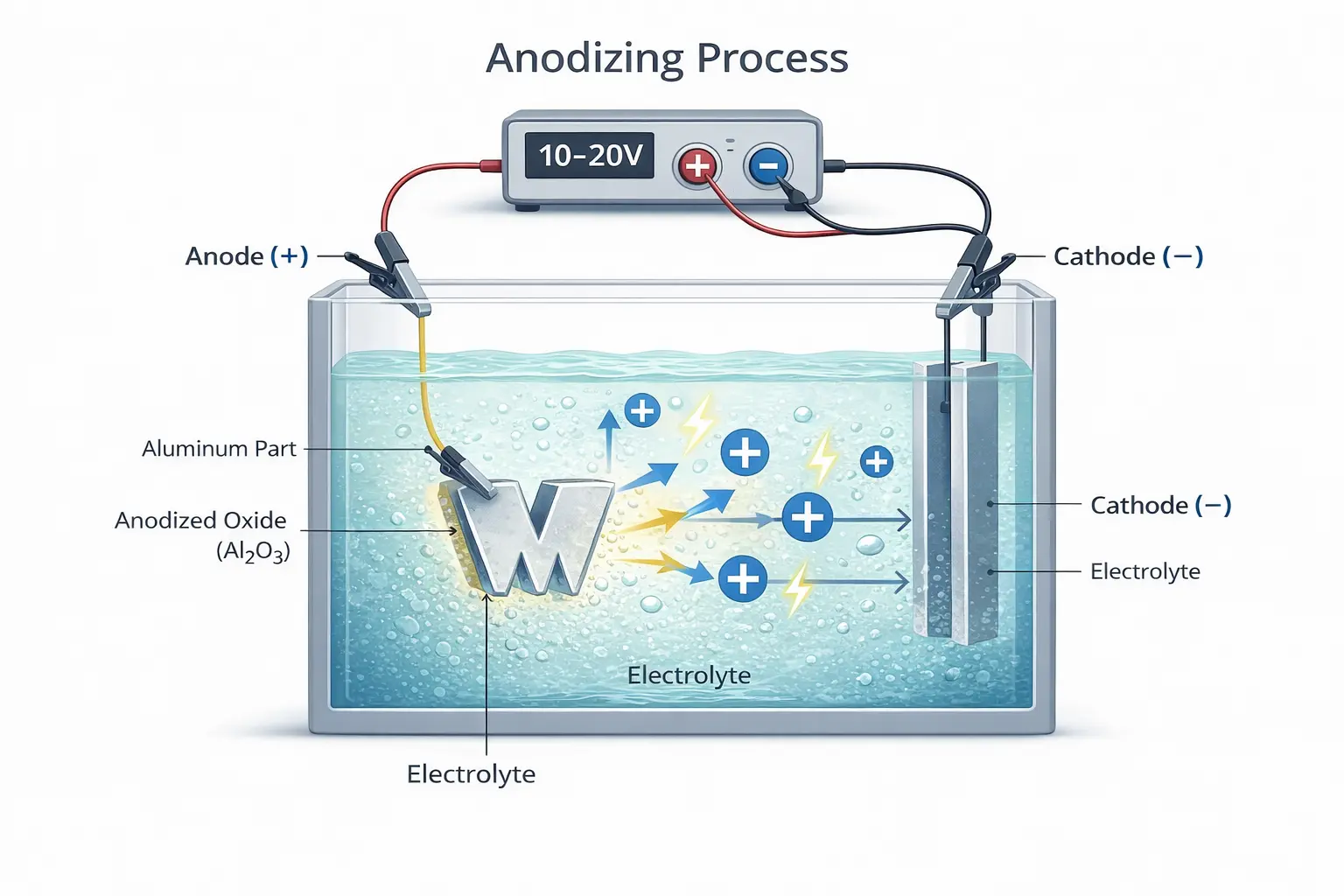

As shown in the image above, anodizing works by immersing a metal part in an acidic electrolyte bath and applying a controlled electric current. This current triggers an electrochemical reaction that causes a protective oxide layer to form on the surface of the metal.

From a technical standpoint, the part being treated functions as the anode in the circuit. When current flows through the system, negatively charged oxygen ions from the electrolyte migrate toward the anode and react with the aluminum surface, forming a stable aluminum oxide layer. At the same time, positively charged hydrogen ions in the electrolyte are reduced at the cathode, which is typically made from T-6063 aluminum alloy or another inert, conductive material. Both the anode and cathode are connected to an external power supply, which provides the energy required to sustain the reaction and complete the circuit.

One of the key advantages of anodizing is its flexibility. The thickness and properties of the oxide layer can be adjusted by controlling process variables such as acid type, voltage, temperature, and treatment time. The resulting surface is significantly harder and more wear-resistant than the base metal, while also remaining smooth and porous enough to accept dyes or additional finishing treatments.

That said, anodizing does have its limitations. Color options are relatively limited by the chemistry of the process, and although the oxide layer is durable, deep scratches cannot be easily repaired without being noticeable. For this reason, anodizing is often chosen where long-term performance and a clean, uniform appearance are more important than cosmetic touch-ups.

Imagine aluminum as a loyal companion—light, strong, and always ready to help, but a little sensitive to the world around it. Left unprotected, it can scratch, fade, or corrode, just like a friend who forgets to wear a coat in the rain.

Anodizing is like giving aluminum its very own invisible armor. It doesn’t just sit on top like paint or coating—it becomes part of the metal itself, forming a hard, durable layer called aluminum oxide. This layer not only shields the metal from scratches and rust, but can also be colored to make it look striking and unique.

Thanks to anodizing, everyday objects—from a shiny bike frame to a sleek laptop casing—can stay beautiful and strong for years. It’s aluminum’s way of keeping its charm while gaining a little extra toughness, almost like a superhero getting a costume that’s both stylish and practical.

In short, anodizing is more than a process—it’s aluminum taking care of itself, ready to face life’s bumps and scratches with grace and resilience.

Just like anything in life, anodizing has its bright spots—and a few little quirks. Here’s the lowdown, told with a touch of humanity:

Anodized aluminum is like giving your metal a suit of armor. It can handle scratches, everyday wear, and even a bit of rough treatment without losing its charm.

Rain, sweat, or even salty air won’t easily harm it. Perfect for bikes, electronics, or outdoor equipment that need to stick around for years.

Anodizing can add color and shine without paint, so your aluminum can stay stylish while staying strong.

Low maintenance – Unlike a coat of paint that chips, anodizing is part of the metal itself, so it doesn’t flake off. A little wipe now and then is enough to keep it looking fresh.

The protective layer is tough but thin. It’s great for most uses, but if you’re expecting a bulletproof shell, it’s not quite that.

While anodizing can add lovely hues, it’s not as free-form as painting. Subtle and elegant is its forte.

If it gets damaged, you can’t just paint over it. Fixing it often means re-anodizing the piece.

Compared to leaving aluminum bare, anodizing adds a little cost and waiting time, but think of it as an investment in longevity and style.

In the end, anodizing is a gentle reminder that a little care and enhancement can make something already good last longer and shine brighter—sometimes, all it needs is the right protective touch.

Anodizing aluminum might sound like a high-tech secret, but at its heart, it’s a fascinating dance between metal, water, and electricity. Think of it as giving your aluminum a spa treatment that leaves it stronger, shinier, and ready for anything.

The process transforms the surface of the aluminum, creating a layer called aluminum oxide. This layer isn’t just a coat—it becomes part of the metal, making it more resistant to scratches, corrosion, and wear.

Here’s the story of how it happens, in a simple way:

Aluminum has to be clean and free of grease or dirt. Imagine meeting someone new; first impressions matter. A clean surface ensures the anodizing works evenly and beautifully.

The aluminum is placed in an acidic solution and exposed to an electric current. This triggers a chemical reaction that forms the protective aluminum oxide layer. It’s like the metal is taking a dip in a rejuvenating, invisible armor bath.

Once the layer forms, it’s sealed to lock in durability and any colors added. Now your aluminum is ready to face life’s bumps, scratches, or the elements while keeping its shine.

During anodizing, dyes can be added to give the aluminum subtle or vibrant hues. It’s not paint; the color becomes part of the metal, so it won’t peel or fade easily.

In the end, anodizing aluminum is about giving a strong, beautiful material a little extra care—turning it from something already useful into something that’s durable, corrosion-resistant, and visually stunning. It’s like giving your metal a long-lasting glow-up, inside and out.

Anodizing isn’t just one single process—it’s more like a family of techniques, each giving aluminum a slightly different personality. Depending on what you need—strength, color, or durability—you can choose the one that fits best. Here’s a friendly guide:

Think of this as the classic “all-rounder” of anodizing. It’s the most common type, offering a good balance of durability, corrosion resistance, and the ability to take on beautiful colors. Perfect for everything from bike frames to electronics casings.

This is aluminum’s version of a tough armor. The layer it produces is thicker and harder, able to withstand scratches, friction, and harsh conditions. Industrial parts, tools, or anything that faces serious wear often gets this treatment.

The gentle and subtle one of the family. The layer is thinner but still corrosion-resistant, ideal for delicate parts that need to maintain precise dimensions. Think aerospace components or intricate machinery.

Sometimes, anodizing isn’t just about protection, it’s about style. By adding dyes or organic finishes, aluminum can get vibrant, lasting colors without paint, staying beautiful while keeping all the benefits of anodizing.

In short, anodizing is like giving aluminum a tailored outfit. Whether it’s a subtle, precise suit, a tough industrial coat, or a colorful, stylish jacket, there’s a type for every occasion.

Anodizing doesn’t just protect aluminum. It lets it show off its personality. Unlike paint that sits on top, the colors from anodizing become part of the metal itself, so they stay vibrant and resistant to fading, scratching, or peeling.

Here’s a little tour of the shades aluminum can wear:

The classic look. It keeps aluminum’s natural shine, subtle yet elegant. Perfect when you want strength without altering the original beauty.

Sleek, modern, and timeless. From electronics to automotive trim, black anodized aluminum has that understated confidence.

Adds warmth and a touch of luxury. Often used in architecture, jewelry, and decorative hardware.

For when aluminum wants to show off a little personality. These colors are durable, vivid, and perfect for projects that need style and strength.

The magic of anodizing colors is that they’re not just skin-deep. They’re part of the aluminum, giving it a lasting finish that’s beautiful, protective, and uniquely yours.

Anodizing is a process that strengthens aluminum by creating a protective layer on its surface. It improves durability, prevents corrosion, and can add color.

Anodized aluminum lasts longer and stays looking good even in tough conditions. It is low maintenance and more resistant to scratches and wear compared to untreated aluminum.

Yes, anodized aluminum can take on a variety of colors that become part of the metal. The colors stay vibrant and do not peel or fade easily.

Absolutely. Anodized aluminum is resistant to corrosion and UV light, making it ideal for outdoor furniture, architectural panels, and vehicles.

Minor scratches can be cleaned and polished but deep damage usually requires re-anodizing the piece. The process is permanent so repairs are limited.

The protective layer adds a tiny thickness to the surface but it is very small and does not significantly affect dimensions.

With normal use and proper care, anodized aluminum can last many years while maintaining its strength and appearance.

Aluminum is everywhere in our lives—from sleek gadgets to precision machine parts. But on its own, it can be vulnerable to scratches, corrosion, and wear. That’s where anodizing comes in. By forming a protective layer on the surface, anodizing not only strengthens aluminum but also allows it to shine in a variety of vibrant colors. It’s a perfect blend of durability and beauty, giving everyday objects a little extra resilience and personality.

Whether you need parts that can withstand harsh conditions, maintain their aesthetic appeal, or simply last longer, anodizing makes aluminum ready for the challenge. And when it comes to turning your ideas into high-quality, anodized aluminum components, Winsun Proto is here to help. With advanced CNC capabilities and a commitment to precision, we bring your projects to life with unmatched quality and reliability.