Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

Running a successful business in the 21st century involves making agile decisions and keeping up with the market. In this article, we discuss the benefits of short-term manufacturing, a modern form of entrepreneurship that has been adopted by companies for today’s dynamic marketplace.

A short-term production is a bold approach to production that favors short-term trades over long-term production. It enables entrepreneurs to diversify their risk portfolio by taking ownership of different product lines and managing every project down to the last detail to maximize profitability.

In economics, the term short-term production refers to production in which at least one resource is fixed. This fixed resource can be machinery, labor, supplies, or time. Consequently, the total output is limited. The goal then is to optimize performance within this boundary.

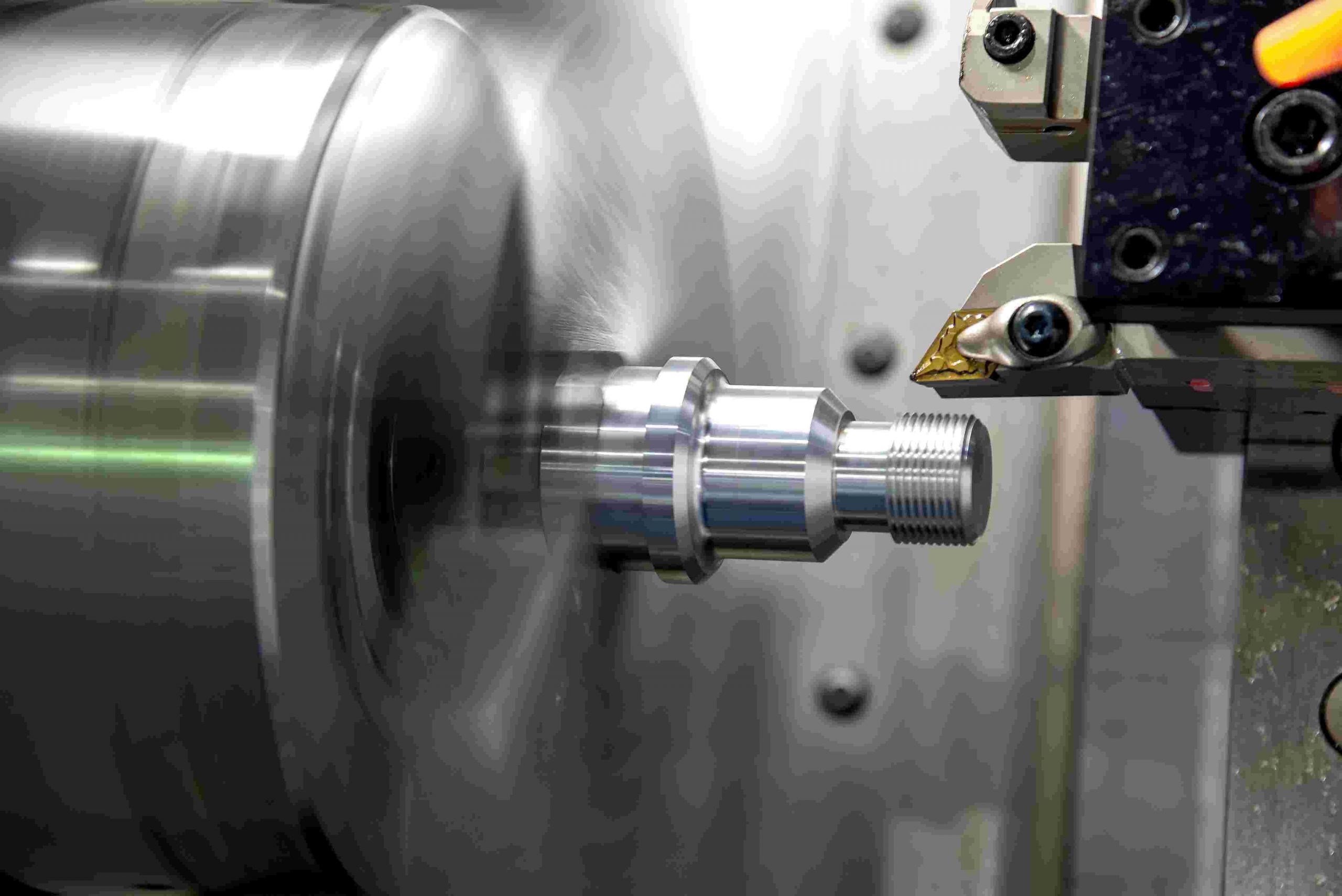

Although this approach may seem unproductive at first glance, it nevertheless promotes the efficiency of business operations. In particular, through the use of cutting-edge technologies such as Industry 4.0 and CNC rapid prototyping, significantly higher yields can be achieved with products than with conventional mass production.

Now that the basic idea behind low-volume production is clear, let’s move on to the main topic. Below we will highlight 8 advantages of small-batch manufacturing that make it a viable business approach.

Customer feedback is an essential factor in the commercial success of a product. One of the most important benefits of low-volume manufacturing is that a company can quickly collect and act on customer feedback.

Once the first batch of a product hits the market, a feedback loop is established with consumers. Business experts can analyze this feedback to identify and diagnose manufacturing defects, incorporate changing market trends into the design, and even identify untapped market segments.

In this way, companies can significantly improve their profitability and brand image.

Most of the benefits of low-volume manufacturing stem from the fact that it revolves around rapid manufacturing technologies. With such manufacturing techniques, product developers can easily test multiple design variants within a short time frame.

This activity can boost enormous quality boost in the product development phase. Numerous prototypes can be shown to customers to receive constructive feedback and steer the design process in a productive direction. In addition, functional prototypes are also very effective when it comes to eliminating usability problems.

What is special about small series production is that all of this can be done while the product is on the market. Updates are easy to make as there is only a small batch of products on the shelves at a time.

Ultimately, business is about optimizing costs. Among the many advantages of short-run production is its positive impact on the cost of doing business.

Large-scale production often requires large investments in the form of equipment, personnel, and an in-house supply line. While these requirements exist even with short-term production, companies have the luxury of managing their resources according to their current production schedules.

Managers can choose to invest in relatively cheap assets that best suit their short-term production schedule. In addition, resources such as labor and inventory levels can also be matched to current needs to save costs. For example, a company may decide to rent a CNC machine for its 3D prototyping needs instead of buying it if the need is only temporary. This saves a fortune in procurement, maintenance, and resale.

Production time is directly related to productivity. It is therefore one of the most important advantages of small series production.

Companies that follow this model tend to take on short-term projects that take less time. The manufacturing processes are the same as for mass production, but the strategy of conducting production in small batches saves time.

In addition, time can also be saved by concentrating a large part of the company’s resources on the respective project and by using fast technologies such as rapid tooling.

One of the most important advantages of small series production is the saved storage space. In contrast to large-scale production, only limited batches are produced here.

Manufacturing facilities produce slightly more than short-term demand, eliminating the need for excessive warehousing and inventory control. While this may seem unwise, it’s not as risky as it seems, since today’s rapid prototyping allows companies to easily adapt to rapid changes in demand.

It, therefore, makes financial sense to plan production in the short term and save storage space.